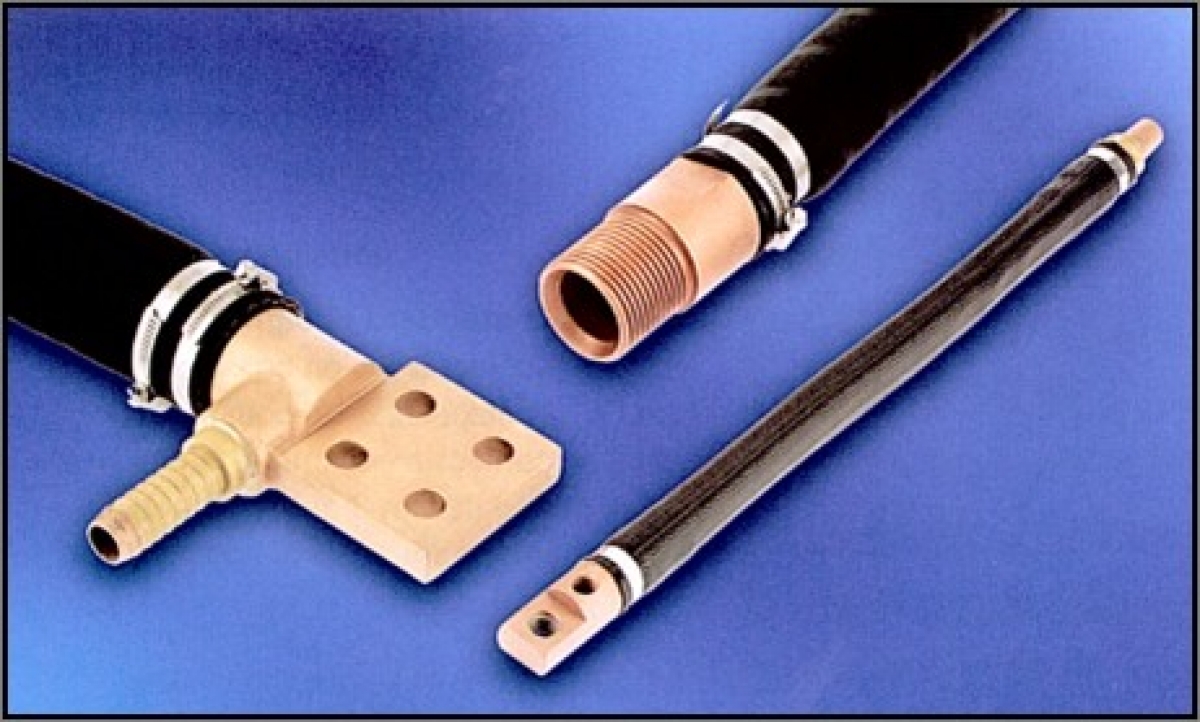

Water cooled connector

Construction

These cables are formed by a copper spring core coated with a copper braid, with jacket neoprene and terminals with electric and water connexion, allowing for some very low bending radii and consequently great ease of handling.

Terminals suiting the needs of each application are welded at the ends of the required length of cable.

Nevertheless, the main feature is the elimination of heat caused by the high current flowing when welding, by the water flowing through inside of the cable.

Characteristics

Copper braid by copper spring with section a diameter request for electrical current (Ampers) and water (bar) and especial terminals for connection.

Application

The main applications of the water-cooled cables are: Electrochemistry; welding; induction furnaces; electrothermic; feeding of electromagnets; etc.

Construction data

Water cooled cables (FRA/FHA)

Copper braid by copper spring with section a diameter request for electrical current (Ampers).

Terminals (electric and water)

Terminals with electric and water connexion. Made terminal in E-Cu.

Connection for water

Threaded holes large enough to accommodate the tube nozzles are made in the connecting pieces.

Jacket tube rubber

Tube Neoprene resistant for 2 bar. Hermetic resistant.